Born in 2010, Micro Engineering Tech Inc. (METI) is a forward - looking company that sees opportunities in challenges. We empower our teams and provide them a fair opportunity to solve these challenges to build a stronger organization for today and for the future.

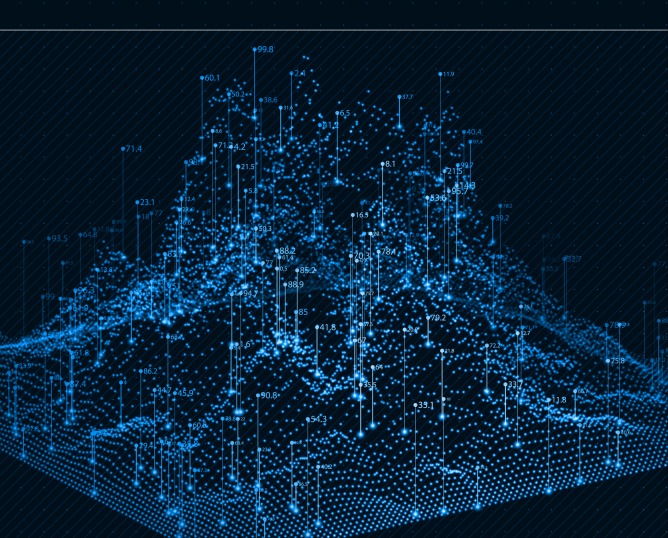

Micro Engineering Tech Inc. (METI) is a pioneering, digital transformation solutions and services provider. We utilize the latest technology in laser scanning, cameras, navigation sensors, UAV, GNSS, data analytics, artificial intelligence, navigation solutions, software as a service, cloud-based solutions for creating HD maps and localization for autonomy and capital asset management. The solutions are multiple dimensions through integration of the 3D derivative products from the HD maps with METI Internet of Things (IoT) platform called Smart Infinity Dimensions (S∞D) that acquire/stream historical and real time data from various sources and sensors (vibration sensors, strain gauges, accelerometers, inclinometers and document digitalization). METI solutions serve several sectors, which are:

METI solutions serve several sectors of smart cities autonomous applications, Energy, Complex Structures and Industrial 5.0

Clients worldwide

Projects Completed

Dedicated Members

Awards Won

S∞D

is a

state-of-the-art digital transformation industry 5.0 solution developed by METI for energy and

construction

industries

BIM models manages graphics and information that allows the automatic generation of drawings, reports, design analysis, schedule simulation, facilities management and more – ultimately enabling the building team to make better – informed decisions.

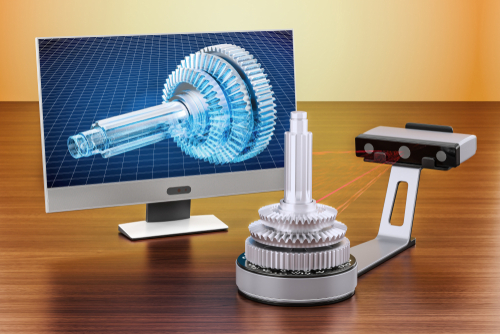

Laser scanning enables a fast, reliable and inexpensive survey of present structures, buildings and their interior.

Using the obtained results from the laser scanner, the user can create volumes, surfaces, layouts, sectional views and more.

Laser scanning is the optimal method for the Building Information Modeling (BIM).

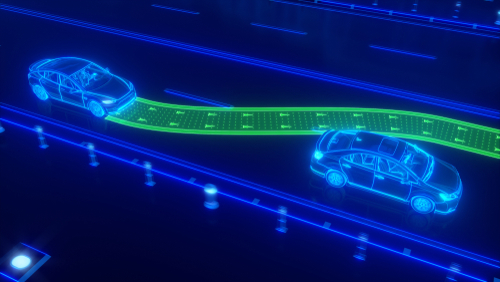

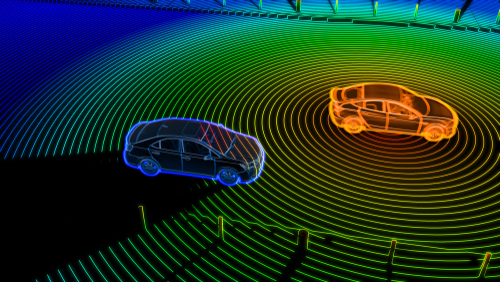

Micro Engineering Tech Inc. (METI) introduces Gulo Gulo solution for the improvement of autonomous vehicle navigation and awareness during autonomous operation, leveraging a number of navigation solutions while lowering costs and improving accuracy levels.

The solution is aided by AI-labelled HD Maps to increase navigation solution accuracy while using vision-based low-cost sensor hardware. The Gulo Gulo solution is an essential tool for achieving true level-4 autonomy.

Using an INS/5G localization solution exploits the prerequisites offered by 5G

technology. The

wide frequency bandwidth and new frequency bands in the mm-wave range provides for

precise position and

angle measurement.

5G localization service is an efficient utilization of

5G-enabled autonomous

vehicular 5G connectivity.

Gulo Gulo uses object detection models to eliminate features from moving/non-static objects. Test simulations were performed on benchmarking datasets and Jointly with our research partners

We offer the autonomous driving system the ability to adapt to different environmental situations and achieve an accuracy level that adheres to safety regulations under harsh conditions. Thus removing the main barrier to level-3 autonomous navigation systems and assisting our clients in exceling and reaching level-4 autonomous navigation.

Complete Software in House Development Experience

METI offers all-round and self-managed outsourced product development services distinguished by its discerning business analysis, conversion-driven UI/UX design, well-honed CI/CD practices, and balanced product evolution.

Sample Projects